How Can I Move Forward If I Cannot Align?

Article by Lora Cecere from Supply Chain Shaman; published on July 12th 2013

For years, as an industry analyst, I have written the statement that “IT and line-of-business teams need to be aligned.” As I finished the report on organizational alignment, I felt a bit silly ever writing this statement. Why? The statement is hogwash. The functions within the line-of-business teams are so misaligned that I cannot imagine that IT could ever align to all of them. In fact, as the research shows, alignment happens through leadership in horizontal processes.

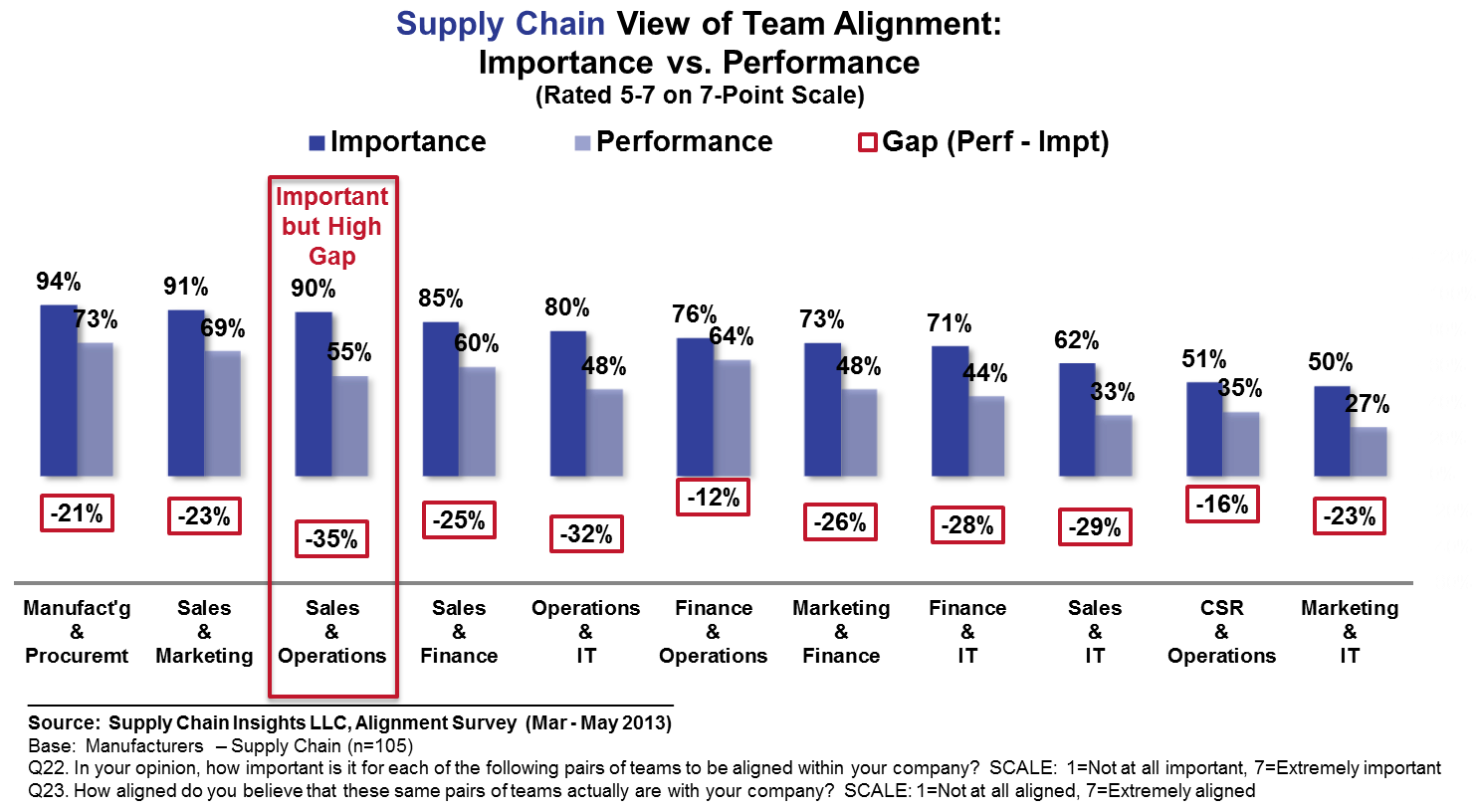

Last month, we finished a study of organizational alignment with over 200 respondents. We asked the IT, finance and supply chain teams to self-assess their views of organizational alignment. The supply chain view is listed in Figure 1. As we tabulated the data for the report, what fascinated me was how differently each of these organizations view functional alignment. For the supply chain team, the largest area of misalignment is between the supply chain and the sales group. I find it interesting that the supply chain teams perceive greater gaps between functions than their counterparts in the finance or IT teams.

Why does it Matter?

Today, for most organizations, things are not going well. Demand volatility is escalating, product portfolios are more complex, and supplier networks are harder to manage. Supply teams are being pressured to reduce costs while demand groups are feeling the squeeze to get the “demand plan right.” The technology investments from the last decade are not meeting expectations. Supply chains are not agile enough. Finger pointing abounds…. Understanding and problem solving often falls short. What is an executive team to do?

Today, for most organizations, things are not going well. Demand volatility is escalating, product portfolios are more complex, and supplier networks are harder to manage. Supply teams are being pressured to reduce costs while demand groups are feeling the squeeze to get the “demand plan right.” The technology investments from the last decade are not meeting expectations. Supply chains are not agile enough. Finger pointing abounds…. Understanding and problem solving often falls short. What is an executive team to do?

Supply Chains are complex systems, and are often not well understood in the organization. In prior studies, the lack of understanding by the executive team is a major barrier. As a result, it is incumbent for supply chain leaders to talk the language of business, hold themselves accountable for corporate performance (versus functional performance) and learn to serve. To align, we have to give up our supply chain geek speak, stop our three and four-letter acronym descriptions and help the organization to better understand the supply chain. In the report, we outline three actions that a team can take today to deploy these skills.

What do we do about it?

1) Define a Supply Chain Strategy and focus on Agility and Orchestration. In this process, be sure that the team members understand that the supply chain is a complex system that must be managed in totality, and that the most efficient supply chain is usually not the most effective supply chain. Use tools like network design optimization and simulation modeling to help people model trade-offs. Force finance and sales teams off of spreadsheets that cannot model the complex relationships of trade-offs. Advance their thinking to use more advanced supply chain modeling tools.

Define what agility is and what it can do for your organization and show why it matters. Do not talk in abstract terms. Make it real. It is not short cycles. It is more than that. It is the ability to have the same cost, quality and customer service given a level of demand and supply volatility. Design the supply chain to perform at these levels of volatility. Focus the organization on understanding the “probability and patterns of demand” and how to design push/pull decoupling points, supplier networks and inventory buffers to improve agility (focusing on form and function of inventory in the supply chain). Use modeling tools to help teams to visualize these concepts.

2) Build Strong Horizontal Processes like S&OP. We have completed two studies now that show that Sales and Operations planning improves both agility and alignment. The impacts are profound. Find a champion within the organization and start working the process. Focus on improving corporate performance –profitability, cycles, revenue growth, customer service and forecast accuracy– against the supply chain strategy.

3) Build an Effective Supply Chain Center of Excellence. Unfortunately, only 1 in 2 supply chain centers of excellence are self-assessed in surveys as meeting expectations. The issues abound, but we cannot let the problems with execution blind us. The value proposition still holds. Supply chain centers of excellence help with metrics alignment and product portfolio alignment between finance and the supply chain team and the supply chain team and marketing. We can see the impact of an effective center of excellence in this report. Too many companies have let their centers of excellence lose relevancy and become academic. The best supply chain centers of excellence serve the business.

Over the course of the last seven years of writing reports, this was one of my favorite reports to write. I think that we took a new angle to understand a tough problem. I would love to hear your feedback. What did you think of the report?